Media reports indicating the potential volume of lubricating oil polluting the world’s seas and oceans due to shaft seal damage or failure should send a clear message to Administrations that this frequently overlooked source of pollution needs to be quickly addressed.

In its evaluation of news clippings over the course of the past few years, Thordon Bearings found more than 100 references to “propeller shaft seal failure and oil leakage into the sea”, the most recent of which was published in the June 2019 edition of Tanker Operator magazine.

This latest article reported a tanker leaking oil after the shaft seals were damaged by rope becoming entangled around the propeller shaft. The 3-lip seal had leaked oil into the sea before divers carried out emergency repairs in Tenerife, Spain.

“Regular reports in the maritime technical press and indeed from hull repair specialists themselves show with alarming frequency that the aft seals of oil-lubricated shaft lines are damaged by either ropes or fishing nets and wholly responsible for this source of pollution,” said Craig Carter, Thordon Bearing’s Director of Marketing and Customer Service.

Press releases issued by a well-known underwater ship repair company reference the regularity in which it carries out repairs to damaged seals. One recent report highlighted work carried out to a general cargo ship with a “leaking stern tube assembly”, while another reported repairs to the damaged seals of a semi-submersible offshore platform in Mexico. Yet another reported repairs to a ship leaking oil in Antwerp, after fishing nets had become entwined around the seal assembly.

“It’s all good business for underwater ship repair companies, of course, but these problematic shaft seals, which account for 43% of all shaftline failures, are not only impacting the marine environment but also the shipowner’s bottom line,” said Carter.

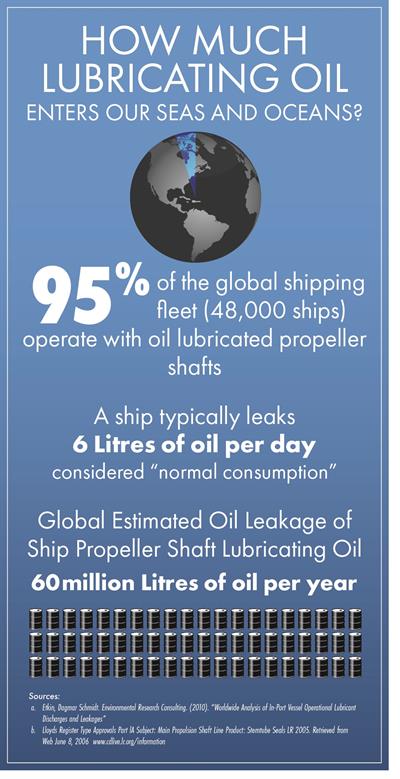

Based on its calculations, Thordon Bearings says that every vessel that operates an oil-lubricated propeller shaft system configured with aft seal, could be leaking on average 6 litres (1.6 U.S gallons) per day – a statistic backed up by research carried out by New York-based Environmental Research Consulting, which found 240 million litres of operational oil is leaked annually from ships.

Terry McGowan, President and CEO, Thordon Bearings, said: “While the list of vessels that have polluted the oceans following damage to sterntube seals is extensive, it is only a fraction of the number of incidents taking place. The only certainty we have is that the amount of oil discharged into the marine environment from faulty or damaged seals is of significant environmental concern and should be addressed immediately by Administrations and regulators. And this doesn’t even include normal leakage from worn seals.”

When there are cost-effective, environmentally-safe alternatives available, it is understandable why environmental concern abounds, especially given the drive to reduce other forms of shipborne pollution.

Indeed, based on the potential impact of this level of oil pollution in its marine environment, the US EPA recommended that “all newbuild vessel operators endeavor to use seawater-based systems for their sterntube lubrication in order to eliminate the discharge of oil from these interfaces to the aquatic environment”. The EPA has included this clause in its Vessel General Permit rules (sect. 2.2.9) since 2013.

“The maritime industry’s continued use of these systems is counterproductive to the excellent work it is doing to clean up our seas with, for example, the introduction of mandatory legislation to reduce emissions, prohibit oily water discharges or prevent the spread of alien aquatic species. We now need regulations to stem the flow of oil leaking from a ship’s propeller shaft,” said Carter.

Referring to an article published in July last year, Carter added: “Ship Insight magazine questioned the continued use of oil-lubricated propeller shafts in the environmentally-driven times in which we now find ourselves. The Editor wrote: ‘With oil lubricated systems, the outboard propeller shaft seals present a risk in that they are expected to fulfill two functions, namely to prevent oil leaking out into the sea, and to prevent seawater from getting in and contaminating the oil. If the seal fails there could be either an operational or an environmental problem…. Water-lubricated sterntube solutions are emerging as the sensible way to go’. We couldn’t agree more.”